Some more aspects of our Industrial Heritage

The catchment area covered by the Colne-Stour Countryside Association (CSCA) has a rich industrial heritage. It is principally a rural agricultural area, both traditionally and to the present time. An article about some of the extractive and manufacturing industries appeared in the CSCA April 2017 edition. This second article explores some further industries, particularly those closely associated with agriculture including milling, malting, brewing and agricultural engineering. The agricultural industry depended upon many other industries for support, particularly prior to improvements in transportation, such as iron foundries and agricultural engineering works. This article briefly explores a few of these industries and surviving heritage.

Milling

Watermills

The milling of grain is one of the oldest industrial activities emanating from farms. The Domesday Book recorded watermills at Assington, Baythorn End, Bures, Cavendish, Clare, Coggeshall, Cornard, Glemsford, Halstead, Hundon, Kedington, Liston, Long Melford, Pentlow, Shalford, Stisted, Sturmer, Sudbury, Wethersfield, Wixoe, Wormingford, the Colnes and theHedinghams. A minority of watermills were later used for other purposes such as fulling mills in connection with the textileindustry and paper mills. A paper mill existed on the Bourne Brook at Greenstead Green, which operated from 1823 to the 1870s when the business relocated to Halstead.

Alderford Mill, Sible Hedingham

Alderford Mill at Sible Hedingham, a grade two star listed building, has been restored and recently ground corn on open days. It is owned by Essex County Council and cared for by the Friends of Alderford Mill whose members provide guided tours. (See website: www.alderfordmill.org.uk for furtherdetails).

Hulls Mill (Hovis Mill), which straddles the boundary between Sible Hedingham and Great Maplestead is now a private residence and the former Clovers Mill at Sudbury has been a hotel for the last forty years. The Townsford Mill in Halstead, which was rebuilt in 1788, was originally a water powered corn mill but in 1828 was acquired by Samuel Courtauld for silk weaving and later converted to steam power. This large attractive building is now an antiques centre.

Box Mill, Halstead.

Other watermills on the River Colne were Box Mill at Halstead, Langley Mill, Whites (formerly Ford Mill) and Colneford (Priory) Mill at Earls Colne, Chalkney Mill at HWite Colne, Wakes Colne Mill, Ford Street and lower Mills at Fordham. There wree two mills sitauted on the Peb or Mill brook tributary of the River Colne, namely a cron mill, and Overshot Mill at Colne Engaine. On the edge of the CSCA area, on the River Pant, were Wethersfield and Codham watermills and, on the River Blackwater, watermills at Bocking and Stisted.

The Mill, Bures.

There were a large number of watermills along the River Stour of which some were in Essex and some in Suffolk. Those on the Essex side were Ashen, Baythorn, Borley, Henny, Liston and Pentlow. In addition there was a watermill at Belchamp Walter on the Belchamp Brook, which was an Essex tributary of the River Stour. The Suffolk mills were at Brundon, Bures, Cavendish, Clare, Cornard, Glemsford, Kedington, Long Melford, Stoke by Clare, Sudbury, Wixoe and Wormingford. (For further information about Bures and other Suffolk watermills please see CSCA newsletter 2011)

Windmills

Windmills did not appear until the late twelfth century and there were examples of all three types, namely tower, smock and post mills, in the area. Among surviving examples are post mills at Bocking and Finchingfield, a tower mill at Gainsford End and the base of a smock mill in Halstead. Other remains include a roundhouse at Belchamp Walter and the base of a smock mill at Bulmer, close to its boundary with Ballingdon.

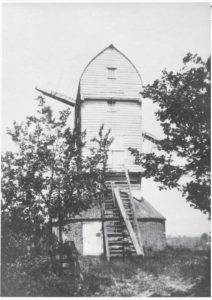

The Post Mill, Cut Maple, Sible Hedingham.

Occasionally, post mills were replaced with smock or tower mills. One example was North Mill at Halstead, where the post mill, which was in existence during the eighteenth century, was replaced with by a smock mill on a brick base during the early nineteenth century. The original post mill at Lamb Lane, Sible Hedingham, was replaced with a tower mill, which contained some of the timbers from the earlier mill. The windmill at Cut Maple was a post mill, which was last in operation during the First World War and finally demolished during the early 1950s.

The Tower Mill, Belchamp Otten.

At Box Mill Lane, Halstead, there were two mills, namely a watermill and a windmill operating side by side. The post mill was blown down during a storm in 1882, but the watermill survived until 1926. A tower mill, near Langley watermill at Colne Engaine, was erected in 1880 for the disposal of sewage.

In addition to the above, there were windmills in Alphamstone, Ashen, Belchamp St. Paul, Belchamp Otten, Birdbrook, Blackmore End, Bures St. Mary, Castle Hedingham, Foxearth, Gosfield, Great Henny, Great Maplestead, Great Yeldham, Greenstead Green, Lamarsh, Middleton, Mount Bures, Pebmarsh, Ridgewell, Stambourne, Steeple Bumpstead, Toppesfield, Wakes Colne, Wethersfield and Wickham St. Paul.

In the Suffolk part of the CSCA area, the base of Highfield Mill at Sudbury, which was a large smock mill, has been converted into a house, and the derelict tower at Chilton Street Clare remains, but another windmill in Clare was blown down in 1875. There were also windmills, with no surviving remains, at Assington, Glemsford, Great Cornard, Great Waldingfield, Hundon, Kedington, Leavenheath, Long Melford, Stoke by Clare and Sudbury.

Hop growing, malting and brewing

Hops were grown commercially for some 300 years until the mid-nineteenth century in the Hedinghams, the Maplesteads, Wethersfield, Colne Engaine, Belchamp Walter and Bocking. Woods were planted in Sible Hedingham, Finchingfield and Wethersfield specifically for hop poles. Wild hops can still be seen growing at various locations along the banks of the River Colne through Sible Hedingham. Oast houses or hop kilns survive at Blackmore End and at Mumford’s Hill, Wethersfield.

Until the early twentieth century, there were numerous maltings in Halstead, Sudbury and the Hedinghams. The small village of Little Yeldham even had two maltings one at Sewells Farm and the other at Upper Yeldham Hall, which partly survives. In the previous century there were maltings at Alphamstone, Bocking, Bures, Coggeshall, Earls Colne, Greenstead Green, Pebmarsh, Shalford, Stisted and two at Great Yeldham. One of the former maltings at Alderford Street Sible Hedingham has been converted into a row of houses.

In addition, breweries often had integral malt-houses such as Mauldons at Ballingdon; Goslings at Bocking; Beards of Coggeshall; Adams & Sons of Halstead and T. W. Raven of Wethersfield Brewery. Brewing was also carried out on a small scale at some public houses, such as James Pearson of The Eight Bells, Belchamp Walter; and Frederick and Sarah Clarke of the White Horse, Sible Hedingham.

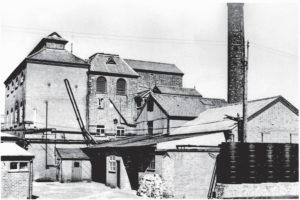

Ward’s Brewery, Foxearth.

There were some ten brewers in Halstead at various times and locations. Two were quite large and existed well into the twentieth century namely Adams & Sons of Trinity Street and G. E. Cook and Sons Limited of Tidings Hill. Some of the remaining buildings of both former breweries have been converted into housing. Another large brewery was at Foxearth where the Ward family were active from 1848 to 1980. The site of the brewery has since been redeveloped for housing. (For further information about breweries please see the article ‘Brewing in East Anglia’ in the CSCA newsletter 2011)

Iron foundries and engineering.

Agriculture was the stimulus for the development of foundries and engineering. The earliest iron foundries were established at Ashen, Earls Colne, Gestingthorpe, Greenstead Green and Sible Hedingham, mainly to produce agricultural implements.

Downs Iron Foundry, Gestingthorpe.

The Gestingthorpe iron foundry, which was in operation for over 80 years, was owned by John Downs and later King Downs. John Downs had started his working life as a blacksmith at Ovington before moving to Gestingthorpe in 1823 and establishing his foundry. He also carried on business as a wheelwright, master brickmaker, farmer and postmaster. The foundry specialised in making a variety of agricultural implements, pig troughs and particularly ploughs. These included the Essex A plough and the popular T.D.O. (Turn Dirt Over) plough. King Downs closed the Gestingthorpe Iron Works in 1908 but continued selling off stock for some years. (For further information see: ‘The Downs Family and Iron Foundry of Gestingthorpe’, by Adrian Corder-Birch, published in Essex Journal, Vol. 40 No. 1, Spring 2005)

Another blacksmith was John Atterton, senior, of Colne Engaine and Halstead whose son, also John, an engineer, was a partner of the Colne Valley Iron Works, engineers and millwrights of Rosemary Lane, Halstead. In 1875 John Atterton, junior, became a mechanical engineer and agricultural machine maker at Haverhill. His business later became well-known as Atterton and Ellis. The former Colne Valley Iron Works was eventually purchased by Charles Portway and became the foundries of Charles Portway & Son Limited and of The Tortoise Foundry Company Limited. These foundries, which employed about 200, existed for nearly a hundred years until closure in 1974. Another Halstead iron founder and engineer was Edward Raven, who was also a machinist and threshing machine contractor. During the mid-twentieth century, Evans Foundry operated in Oak Yard, prior to relocation to Factory Lane West, when it amalgamated with Nokes Foundry, where the foundry of Maycast Nokes Limited continues to operate.

The agricultural engineering works of Whitlock Brothers, Gt.

There were two forage merchants in the area, namely Charles Row at Long Melford and Walter Whitlock at Great Yeldham, who was later succeeded by his son Christopher. At Walter Whitlock’s chaff works at Poole Farm, hay and straw was pressed into bales to provide food for horses and cattle. At its peak, 100 men were engaged sending over 100 tons of chaff to London every week. Walter sometimes had difficulty obtaining parts and repairs to his machinery and therefore encouraged two of his sons to become engineers. They established the foundry of Whitlock Bros. in 1899, which was incorporated as Whitlock Bros. Limited in 1941 and specialised in agricultural engineering. The firm also had a carpenter’s shop where all types of wooden buildings were made mainly for farmers. Agricultural trailers were manufactured and grain drying and storage plant was installed on farms. From 1950 earthmoving machinery, including the well-known Dinkum Diggers, Dumpers and Dredgers, became a speciality. The company eventually employed about 600 people at Great Yeldham and, following a takeover in 1972, the factory closed in 1975. (For further information see: ‘Whitlock Brothers – A history of the family, farms, forage works, foundry and factory at Great Yeldham’, by Adrian Corder-Birch, published 2017)

Another local agricultural engineering company was Blyth and Pawsey Limited, which operated at Ridgewell and Saffron Walden. In Suffolk, Thomas Orbell & Son were agricultural engineers, ploughing and threshing contractors at Clare. They owned several traction engines used for ploughing and threshing and carried out repairs to farm implements and steam engines.

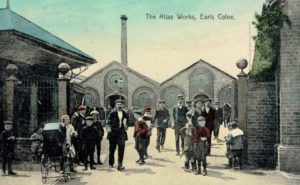

R.Hunt & Co. limited, Earls Colne.

The foundry of Hunts, later R. Hunt & Co. Limited and finally Christy Hunt at Atlas Works, Earls Colne, was originally established by a millwright to provide machinery for water and windmills. It later specialised in the manufacture of all types of agricultural machinery and mechanical power transmission equipment. It employed 300 and eventually closed in 1988, following an existence of about 150 years. (For further information see: ‘Hunt for Machinery – The Rise, Success and Demise of R. Hunt and Company Limited of Earls Colne, 1825- 1988’, by Patricia Burton-Hopkins, published by Halstead and District Local History Society in 1995)

A significant part of the Atlas Works has been preserved and many former buildings converted to other uses. The Victorian buildings, which are grade two listed, have been renovated for commercial uses. The former water tower, built in 1885, is now the Earls Colne Heritage Museum. A Doctors’ Surgery exists and much of the site has been redeveloped for housing. It is pleasing that former industrial buildings have been retained and are still recognisable, which are part of our rich industrial heritage.

Adrian Corder-Birch

Adrian Corder-Birch is a founder member and Vice Chairman of Essex industrial Archaeology Group, which is a subgroup of the Essex Society for Archaeology and History of which he is President. He is a Deputy Lieutenant for Essex and Chairman of the Editorial Board of Essex Journal. His many other positions include being the Clerk to Little Yeldham, Tilbury Juxta Clare and Ovington Parish Council since 1971 and Patron of Halstead and District Local History Society. Following 36 years in the legal profession, he was Clerk to Sible Hedingham Parish Council for ten years until his recent retirement. He is an active member of the British Brick Society and of The Association for Industrial Archaeology. He has been a member of the Colne- Stour Countryside Association for many years, served on the committee for five years and became a Life Member in 1988.

He is the author of the following books:

‘Our Ancestors were Brickmakers and Potters – a history of the Corder and related families in the clayworking industries’ in Gestingthorpe, Castle and Sible Hedingham, Gosfield, Great Yeldham, Bulmer and other locations.

‘Bricks, Buildings and Transport – A history of Mark Gentry, the Hedingham red brick industry, buildings, road and rail transport’ ‘Whitlock Brothers – A history of the family, farms, forage works, foundry and factory at Great Yeldham.’

He is joint author, with his wife Pam, of ‘The Works – A history of Rippers Joinery Manufacturers of Castle and Sible Hedingham’

The above books are available from: Adrian Corder-Birch, Rustlings, Howe drive, Halstead CO9 2QL price £14.95 each plus £2.90 p&p. Cheques in English pounds sterling payable to: Adrian Corder-Birch, please. Any enquiries to: adrian@corderbirch. co.uk