Some aspects of our Industrial Heritage

The catchment area covered by the Colne-Stour Countryside Association (CSCA) has a rich industrial heritage. It is principally a rural agricultural area, both traditionally and to the present time. The numerous brick and timber buildings are the result of the absence of natural building stone, which exists in many other areas. The agricultural industry depended upon many other industries for support, particularly prior to improvements in transportation. The principal industries in the area were milling, malting and brewing, iron foundries and engineering, textiles, woodworks and the extractive industries, particularly brick and tile works. This article briefly explores a few of these industries and surviving heritage.

Extractive industries

-

Chalk and lime

Lime burning was carried out at several chalk pits particularly around Sudbury. The lime was mainly used for agricultural purposes and sometimes chalk was used on the land without burning. The principal chalk and lime contractors were P. H. Jordan of Brundon and Chilton and Allen & Boggis Limited of Ballingdon and Waldingfield Road, Sudbury. P. H. Jordan was also a haulage contractor, coal, sand, gravel and cement merchant.

-

Sand and gravel

The extraction of sand and gravel took place at many locations in the CSCA area. The locations of some of the largest excavations were at Acton, Beazley End (Wethersfield), Brundon, Chilton, Glemsford, Liston, Sible Hedingham and Sudbury. Sand and gravel merchants included George Grimwood & Sons of Sudbury, Thomas Ray of Langley Mill, Halstead and Daniel Cornish of Foxborough Hills, Sible Hedingham. In addition there were numerous small workings throughout the area, many of short duration and long since abandoned. The sites of some of these former pits can still be detected where the landscape has not been restored.

-

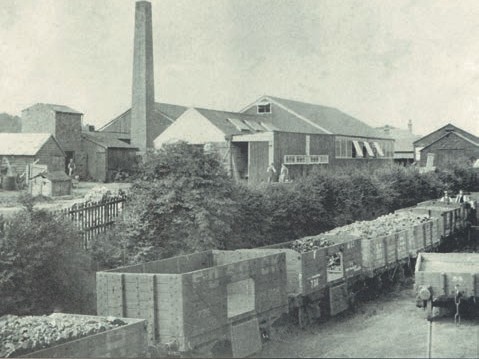

Brick, tile and pottery works

There were numerous brick and tile works in the Colne-Stour area, some of which were very extensive and were major employers. There is evidence of brick and tile making in the Roman period and from medieval times to date. During the last 200 years, brickworks existed in Ballingdon, Bulmer, Bures, Castle Hedingham, Cavendish, Chilton, Clare, Coggeshall, Colne Engaine, Earls Colne, Gestingthorpe, Glemsford, Gosfield, Great Cornard, Great Maplestead, Great Yeldham, Halstead, High Garrett (Bocking), Liston, Little Cornard, Long Melford, Marks Tey, Rayne Hatch (Stisted), Sible Hedingham, Stambourne, Steeple Bumpstead, Stoke by Clare, Sudbury and Wethersfield.

One of the largest manufacturers in the Sudbury area was Allens of Ballingdon, which operated for over 140 years until 1939. They employed 100 men making both red and white bricks and also owned a brick-works at Gallows Hill (now Waldingfield Road). Grimwoods also operated at Gallows Hill from 1900 to 1939 and had another yard at Little Cornard, which continued production until after the Second World War.

At Sible Hedingham there were brickworks owned by Mark Gentry and successive members of the Cornish family. The Corder family owned brickworks at Sible Hedingham, Gosfield and Great Yeldham and managed a brick-works at Castle Hedingham. The Rayner family owned the Maiden Ley Brick Works at Castle Hedingham and a different Rayner family owned two brickworks at Gestingthorpe.

Many of the bricks made at Ballingdon were transported by barge along the River Stour prior to the First World War. Ballingdon bricks were used in the Albert Hall and Liverpool Street Station. The brickworks at Castle and Sible Hedingham, which were fortunate enough to have sidings onto the Colne Valley Railway, could easily transport their bricks to London and other towns. Mark Gentry even exported bricks to Africa, Egypt and Ireland. These brickworks gradually closed during the twentieth century, with the final closures taking place during the early 1950s.

During the late Victorian and the Edwardian periods the industry employed several hundred men, making millions of bricks, mainly red but some white, together with roofing tiles. Some brick and tile works, such as that owned by the Corder family at Southey Green, Sible Hedingham made pottery including chimney pots, flower pots, a variety of pottery for kitchen and dairy use and large quantities of drainage pipes. There were also potteries at Castle Hedingham, Gestingthorpe and Great Cornard. As brickmaking was seasonal work (spring to autumn only), some men found work in maltings during the winter, which applied in Sible Hedingham and Sudbury. (The malting industry will be covered in a future article). There are only two surviving brickworks in Essex and they are both in the area covered by the CSCA at Bulmer and Marks Tey.

The above extractive industries resulted in the employment of some personnel in a number of service industries such as the building trades, railways and transport companies.

Woodworks

A manufacturing industry, which was necessary for the building trade, was woodworking and it provided significant employment in the CSCA area. The major woodworks were Rippers at Castle and Sible Hedingham and Wheelers at Sudbury and Chilton.

Ripper’s joinery works commenced at Castle Hedingham and moved to Sible Hedingham in 1899. They specialised in producing wooden windows, doors, staircases, television cabinets and numerous other items. A variety of wooden products were manufactured to help the war effort in the Boer, First and Second World Wars. The factory was conveniently situated next to the Colne Valley Railway onto which it had sidings for delivery of tree trunks and despatch of completed joinery. Rippers Limited became a major employer with a staff of up to 640 and remained in family control until 1973 when taken over by the Bowater Corporation. Following further takeovers the factory closed in 2009 and the site is now being redeveloped for housing. Rippers Limited owned a subsidiary company namely The Sible Hedingham Red Brick Company Limited, which made bricks at Purls Hill from 1919 to 1953.

Wheelers started in 1860 with a small timber yard at King Street, Sudbury where it had the benefit of a siding from the Stour Valley Railway. They had sawing, planing and moulding mills and apart from timber merchants were also slate and cement merchants and dealers in sanitary ware. At Chilton, in 1910, they succeeded E. & E.C. Gibbons as manufacturers of red and white Suffolk bricks, which ceased in 1935. During the Second World War, Wheelers opened a timber mill on their former brickworks site at Chilton to help the war effort, when they supplied timber for boats and railways. After the war they continued to supply timber for railways but in addition supplied wedges for mines and wood for furniture making. In 1946 a joinery department began to produce doors, windows and staircases.

The premises in King Street became their builder’s merchants’ depot for the supply of building materials. The employees increased from 14 in 1918 to over 100 during the late 1940s. When the King Street depot closed in 1965, the timber mills at Chilton continued to operate until quite recently.

W. & A. Hitchcock Limited of Station Road, Sudbury specialised in English and Foreign timbers and were also coal merchants. This business was established in 1855 when wood was carted by teams of horses and sawn by hand over a pit. The sawyers were later joined by wheelwrights, when wagons and tumbrils were manufactured together with ladders, gates and coffins. The sawyers also cut out timber for lock gates and barges on the River Stour.

The woodworks, steam turnery and sawmills of Henry Cocksedge & Son in Halstead, which operated between 1860 and 1959, produced small wooden objects, mainly with lathes, such as handles, rollers, polo balls, skittles, bungs for beer barrels and all types of turnery ware.

Maplestead Woodworks Limited of Oak Road, Little Maplestead, specialised in the production of spills. In 1963 thepremises were taken over by Stephen Sampson & Son, manufacturers of wooden household furniture, which was sold worldwide.

In 1973 JSR Joinery Limited, a specialist joinery company was established at Woodpecker Court, Poole Street, Great Yeldham. In 1982 C. R. Timber Limited was incorporated and specialised in the manufacture of wooden roof trusses, operating from the former airfield at Earls Colne.

Also at Earls Colne, T & A. J. Mann Limited was a long established company of timber merchants. Trees, including oak, ash, elm and willow were collected and taken to their works for cutting into planks for builders, implement makers and undertakers. Willow trees were despatched to cricket bat makers and the bark from oak trees was peeled off and taken to Halstead Tan Yard.

Tanneries

There was a tannery at Alderford Street, Sible Hedingham and two in Halstead. The last one, trading as Hugh Brown & Co., was in operation until 1960. It was in production for nearly 400 years and Halstead had the reputation for supplying some of the finest leather in the world. The buildings were demolished in 1962 and the site levelled to become Chapel Street car park. At Great Yeldham, James Scotcher was a fellmonger at the appropriately named Leather Lane until he retired during the mid 1860s.

Commemorating our industrial heritage

It is pleasing that during the last couple of decades, architects and planners have been increasingly aware of the importance of our industrial heritage. This has occurred at Sible Hedingham where recent plans have incorporated the rich industrial heritage of the village and its beautiful riverside setting. The majority of the artwork has been functional as well as decorative and examples are as follows:

- A decorative metal safety barrier around a deep drain along the new Riverside Walk has incorporated hops, corn and trees.

- A metal chimney sculpture to reflect the former industrial chimneys in the village at its two watermills, brickworks and joinery works. The new chimney, on a red brick base, contains plaques depicting the history of Sible Hedingham, including its former industries.

- Walls built with red bricks made by Bulmer Brick & Tile Co.Limited, some with former Hedingham moulds, to commemorate the former Hedingham brickmaking industry. These walls have incorporated place names such as Cousins Yard, Alderford Farm and Aleys Barn.

- Steel benches and waymarkers featuring local industries and wildlife.

A recent residential development will shortly result in another ten acres of land, formerly owned by industrial companies, being allocated under a S106 Agreement for an extension to the existing Riverside Walk and for a Nature Reserve. With careful thought and planning the legacy of our industrial heritage can benefit wildlife and the countryside.

Adrian Corder-Birch

Adrian Corder-Birch, D.L., is a founder member and Vice Chairman of Essex industrial Archaeology Group, which is a sub group of the Essex Society for Archaeology and History of which he is President. He is a Deputy Lieutenant for Essex and Chairman of the Editorial Board of Essex Journal. His many other positions include being the Clerk to Little Yeldham, Tilbury Juxta Clare and Ovington Parish Council since 1971 and Patron

of Halstead and District Local History Society. Following 36 years in the legal profession, he was Clerk to Sible Hedingham Parish Council for ten years until his recent retirement. He is an active member of the British Brick Society and of The Association for Industrial Archaeology. He has been a member of the Colne-Stour Countryside Association for many years, including committee service and became a Life Member in 1988.

He is the author of the following books:

‘Our Ancestors were Brickmakers and Potters – a history of the Corder and related families in the clayworking industries’. This book includes many brickworks and potteries in Gestingthorpe, Castle and Sible Hedingham, Gosfield, Great Yeldham, Bulmer and other locations.

‘Bricks, Buildings and Transport – A history of Mark Gentry, the Hedingham red brick industry, buildings, road and rail transport’. This book looks at the Hedingham red brick industry in depth, buildings constructed with Hedingham bricks and transportation by the Colne Valley and other railways.

He is joint author, with his wife Pam, of ‘The Works – A history of Rippers Joinery Manufacturers of Castle and Sible Hedingham’. This book covers the history of the joinery works from the struggles of the three founder brothers in the 1890s, to its growth into a major employer in the 1970s.

The above books are available from: Adrian Corder-Birch, Rustlings, Howe Drive, Halstead CO9 2QL Enquiries to: adrian@corder-birch.co.uk

It is intended that this initial article about the industrial heritage of the Colne-Stour area will be followed in future years by more articles about the history of other industries, which once operated in the area.